Although problems associated with high G were experienced by the end of World War 1 and during the Schneider Trophy Races of the 1920s, little work was carried out in the UK on the effects of G and G protection prior to World War 2. However, in June 1939, with war looming, it was agreed that work on G protection for aircrew was urgently required. These early studies were conducted in service aircraft, but this proved problematic as it was difficult, if not impossible, to replicate the required high G profiles in a controlled way, it was not possible to install appropriate recording equipment in the aircraft to measure the necessary physiological data and there was no way to provide suitable medical supervision.

So it was decided that the UK should procure its own centrifuge – a machine capable of replicating the high G environment of flight, but under controlled, repeatable and safe conditions with suitable recording facilities and medical supervision. The main purpose of the centrifuge was to gain a better understanding of how G affects the human body and develop appropriate countermeasures, with additional purposes being testing of aircraft equipment, clinical investigation and training.

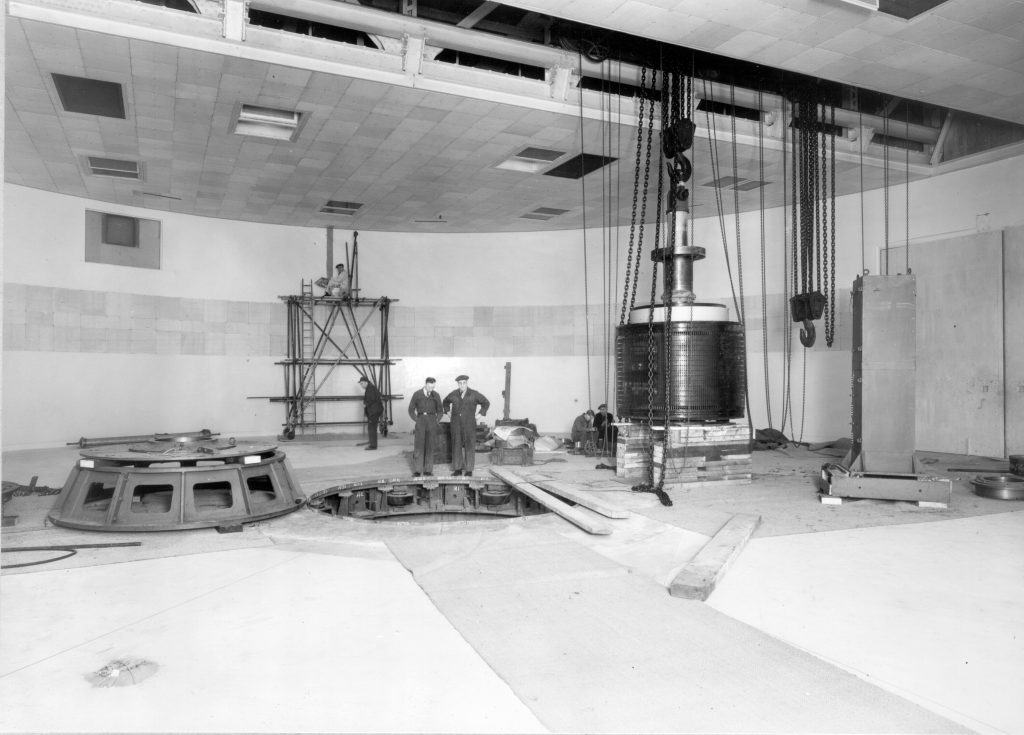

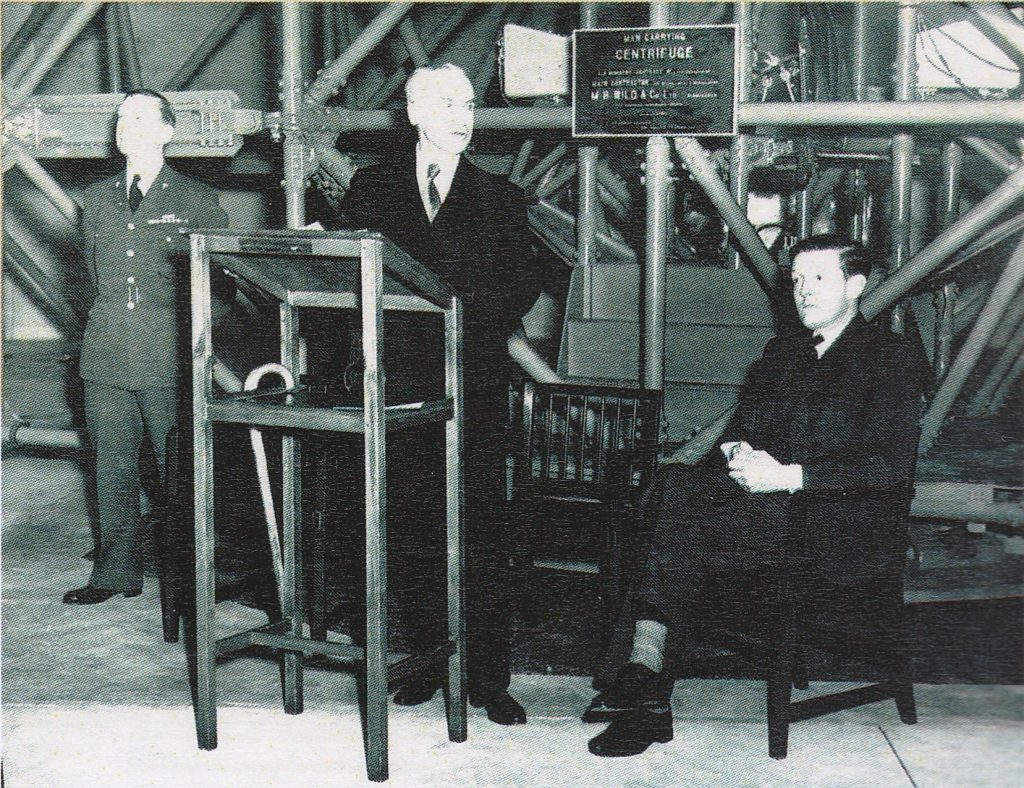

The centrifuge was designed by the Air Ministry with its main features finalised in 1947. The main contract was placed with M B Wild and Co Ltd, the tube structure of the arm was fabricated by Air Service Training Ltd, the gondolas were made by M L Aviation Ltd, and the electrical power and the control system were made by the General Electric Company Ltd. Construction took place between 1951 and 1955 at a total cost of £350,000. The first centrifuge run took place on 18 April 1955 and the facility was formally opened by Lord Thurso on 17 May 1955.

It was then in virtually continuous use until its final run on 4 March 2019, by when it had completed a total of 122,133 runs. During this time it has played a key role in research into the High G environment and contributed to many world-leading technology developments in this area by British aviation medicine pioneers which have since been adopted for all modern combat aircraft worldwide. In its 64 year history, the centrifuge has only had one known failure when an overspeed occurred taking it up to about 15G during a manned test of the Typhoon Aircrew Services Package. Fortunately no one was injured due to the quick reaction of the experienced centrifuge subject. A new modern centrifuge was opened at RAF Cranwell on 4 February 2019.

The centrifuge today has changed very little from the original 1950s facility. Over the years it has undergone some limited updates (eg new slip ring assembly in the 1970s, gondolas updated in 1972, brake systems replaced in 2006), but the basic centrifuge, control room, plant room, motor, control circuits and method of operation remain unchanged, a unique and impressive example of 1950s British engineering.