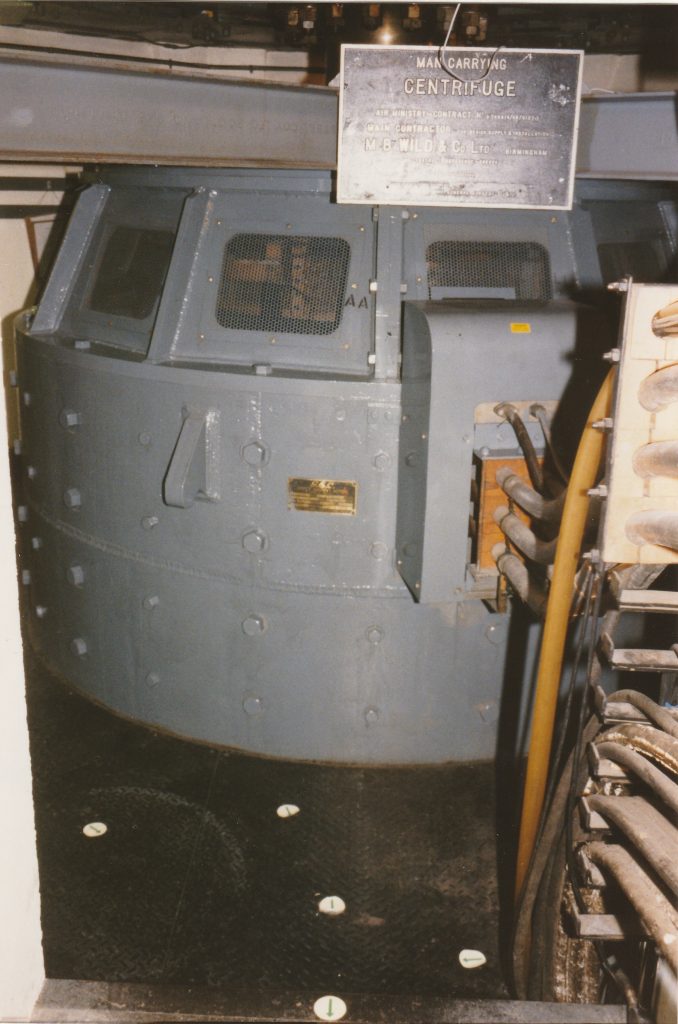

Opened in 1955, the Farnborough Centrifuge (or the Farnborough Man-Carrying Centrifuge to give it its full, official name) was the first machine in Britain that was able to test human subjects and their equipment under the effects of high-G flight, without exposing them to the potentially fatal risk of actual test flights.

For over 60 years, the centrifuge remained at the forefront of research and training by the Royal Air Force Institute of Aviation Medicine. The only centrifuge designed and manufactured by British engineers, it is believed to be the oldest example in the world that has hardly changed from its original state.

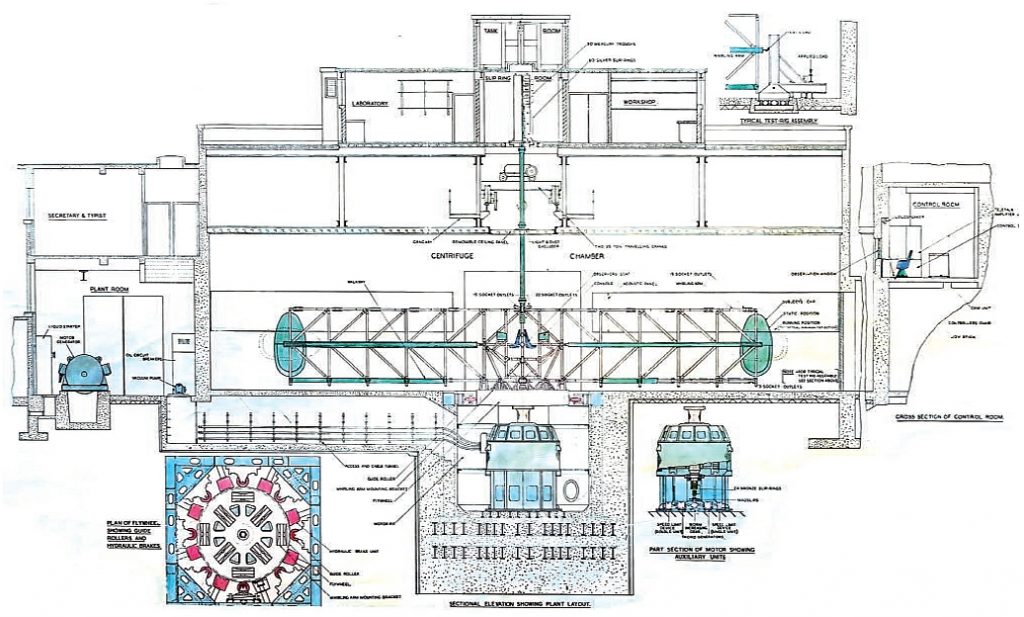

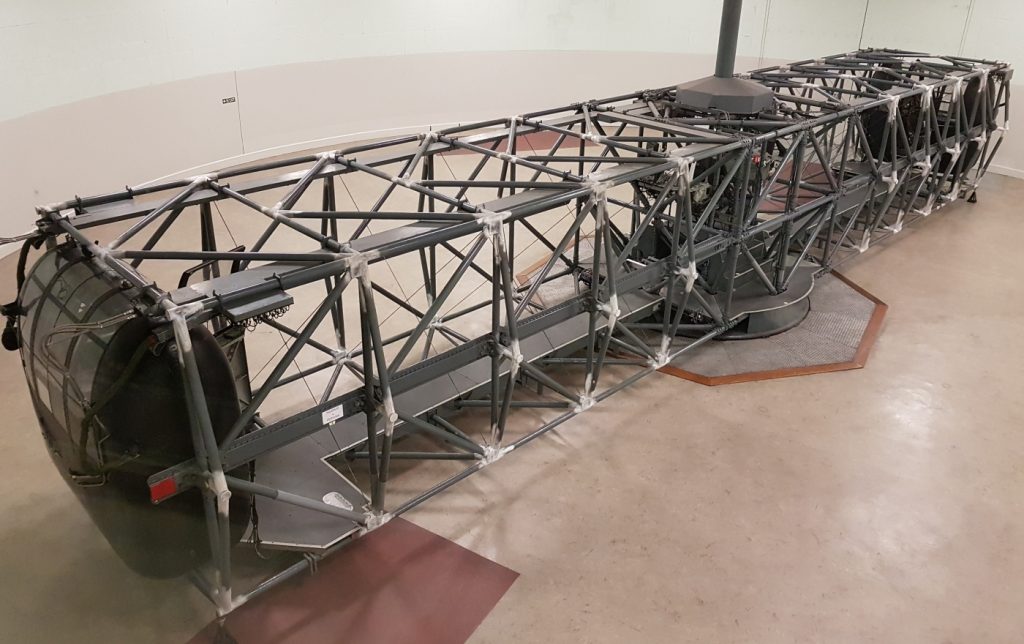

The centrifuge is housed in a circular steel reinforced concrete building. The main structure of the centrifuge is a horizontal arm of high tensile tubular steel and duralumin construction measuring 62.5 ft in length, pivoted at the centre and rotating in a clockwise direction under a precisely controlled cycle of acceleration and deceleration. At each end of the arm is a pivoted gondola which can be accelerated up to 30G (115 mph / 54 rpm), although this is restricted to a maximum of 9G (63 mph / 30 rpm) with a person inside.

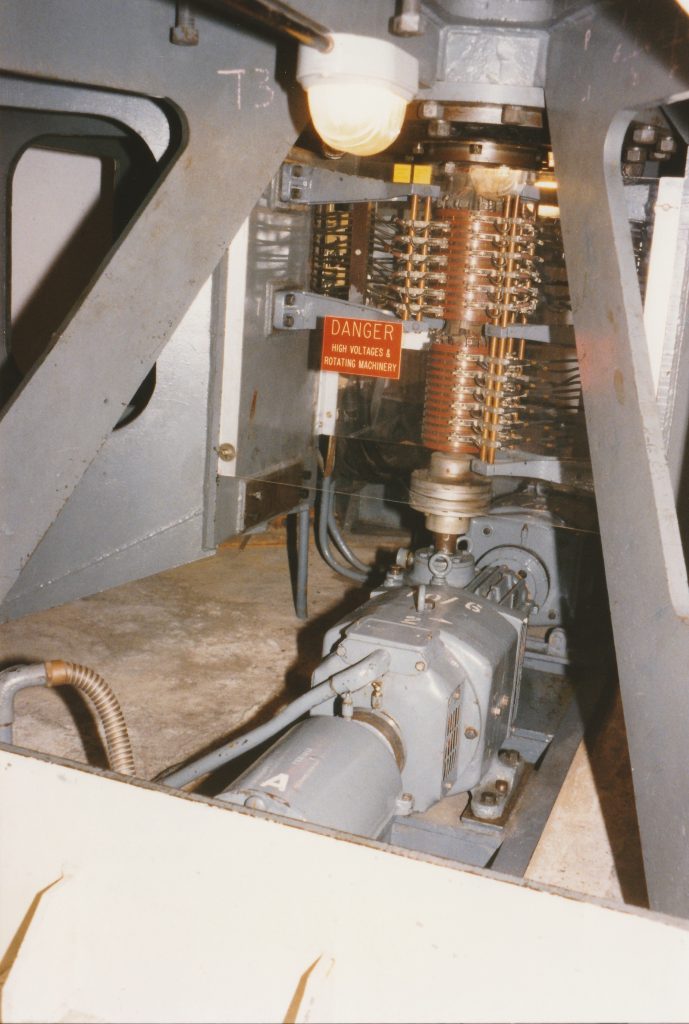

The centrifuge arm is mounted on a 12 ton 12 ft diameter flywheel attached to the vertical spindle of a 1 Megawatt direct current electric motor installed in a central pit in the centrifuge chamber, rated at 1,350 horsepower. The overall rotating weight of the centrifuge motor, flywheel and centrifuge arm is 40 tons. Below the motor is a gearbox of ratio 3:43 which drives two tacho-generators (which provide the feedback signal for the control system) and three overspeed devices; and the bronze slip ring assembly that supplies power and other services to the centrifuge arm and gondolas.

Centrifuge motor

Bronze slip ring assembly

Adjacent to the centrifuge chamber is the Plant Room which is the power house of the whole building. The heavy electrical machinery in this room takes power from the national grid and converts it to drive the centrifuge arm under precise control of speed to generate the required levels of G (the G profile) using a Ward Leonard motor speed control system. Almost all this machinery is unchanged from the 1950s.

Overlooking the centrifuge chamber is the Control Room which houses the control desk, the programme cam unit and various audio-visual communication devices. The cam unit automatically controls the G profile of the centrifuge, using a number of interchangeable cams, each of which is designed to give a different peak G. It is also possible to control the G profile manually (eg to simulate air combat manoeuvres) using a joystick at the control desk, movement of which either accelerates or decelerates the arm by acting on the programme cam driving motor through a drum controller.

With the agreement of the owners, Raintree Developments Ltd, the Farnborough Air Sciences Trust (FAST) can now exclusively offer comprehensive guided tours of this unique facility, not normally open to the general public.